Lean project management is a methodology focused on maximizing value while minimizing waste throughout a project’s lifecycle. The lean approach is centered around efficiency. It’s all about cutting out the fluff — whether that’s unnecessary steps, wasted resources, or downtime — and focusing on what adds the most value.

Featured Partners

What is lean project management?

Inspired by the Toyota Production System (TPS) in the mid-20th century, lean principles were initially applied to manufacturing but have since expanded to other industries, including project management. You can think of lean project management as a “less is more” approach to running projects.

This means fewer resources are used to generate more value by eliminating inefficiencies and continuously improving processes. Lean project management seeks to streamline workflows and ensure each task gets you closer to delivering exactly what your customer needs without extra baggage weighing you down.

5 principles of lean project management

Lean project management revolves around five core principles that guide teams in delivering value without the clutter.

Specify value

The first principle has you answer, “What am I really delivering to my customer?”

Understanding the real value you are delivering to the customers, whether external or internal, involves digging into what they truly care about and would be willing to pay for. For project teams, this means aligning efforts with the customers’ priorities and making sure that each task directly contributes to the end goal.

For instance, in software projects, this could involve focusing on features that solve critical user pain points rather than adding unnecessary or ineffective features. Another example would be a sales project that centers around iterating a specific aspect of the sign-up process that affects a targeted demographic.

Map the value stream

Once you’ve pinpointed the value, it’s time to map out the entire process from start to finish. In the lean methodology, this is known as the value stream.

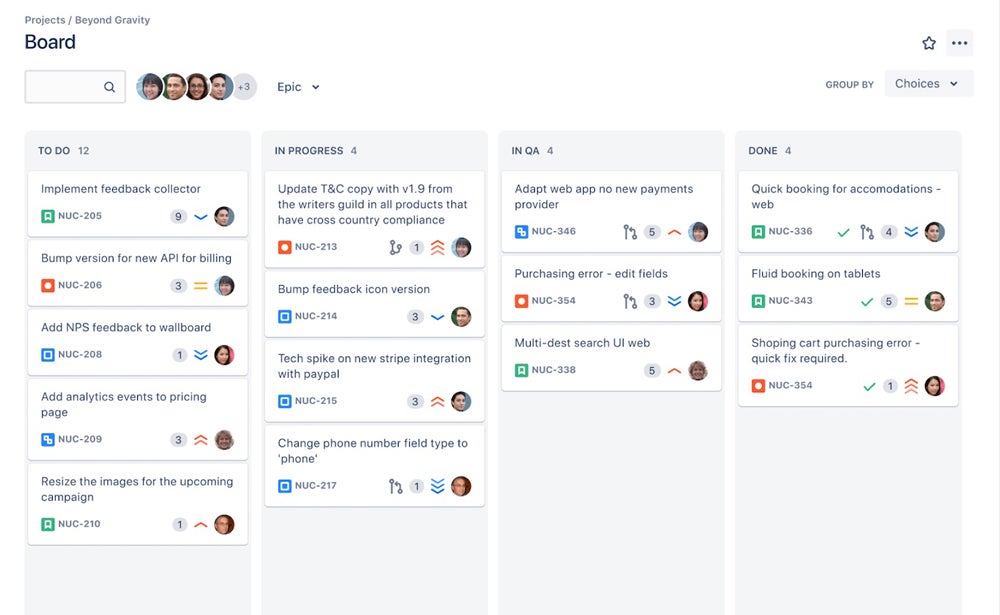

Mapping the value stream isn’t just about listing tasks, but about identifying every step that adds value and eliminating waste wherever possible. A common tool used for this is the kanban board, which is quite popular in agile project management software.

A kanban board visually represents a workflow and helps teams see where bottlenecks or delays might occur. This step encourages transparency in operations and allows your teams to refine processes as the project evolves.

For those managing more structured processes like waterfall project management, mapping the value stream can help to identify areas where delays or inefficiencies commonly occur.

Create flow

Flow is the heart of lean project management. After identifying and cutting out waste, you want to introduce a tight sequence by creating a process where tasks move seamlessly from one stage to the next without unnecessary delays.

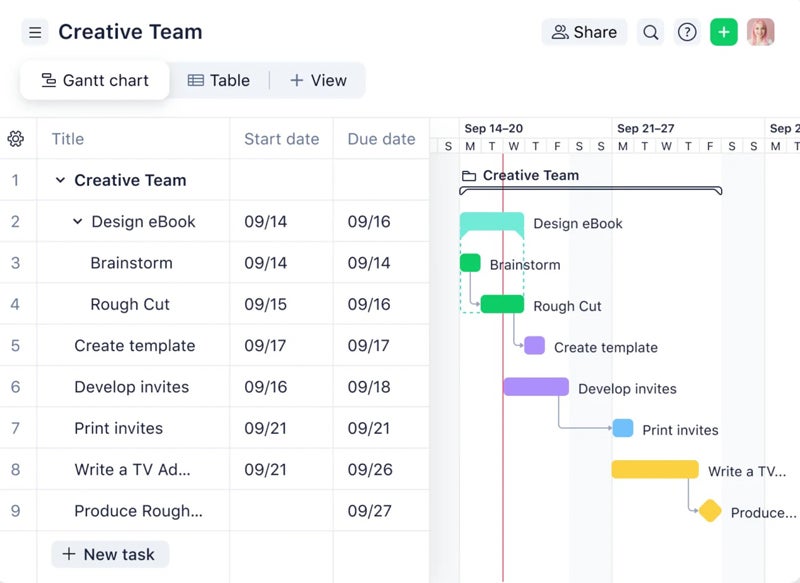

Some project teams will use a Gantt chart to visualize the flow and better see how steps in the project relate to each other. This type of tool is particularly useful for projects with a large number of task dependencies.

One way to ensure flow is by addressing bottlenecks. Where does work tend to pile up or slow down? For example, a team might find that too many approvals or handoffs between departments are causing delays and rework the process to avoid those choke points. Or they may discover that the workload is not balanced among team members and adjust that to more evenly distribute tasks.

SEE: Learn more about Gantt charts and how they can be utilized for lean project management.

Establish pull

The fourth principle of lean project management builds on the concept of just-in-time production. Instead of pushing work through the pipeline, lean emphasizes a “pull” system, where tasks are initiated only when there is a demand for them.

This keeps the team from overproducing or wasting resources on features or tasks that might not be needed. In project management, a pull system ensures that resources and time are allocated efficiently, focusing only on what adds value in the moment.

Pursue perfection

Lean project management isn’t just about getting things done — it’s about continuously improving the way things are done. As a result, this principle encourages a culture of ongoing reflection and refinement.

After the successful completion of each project, or even during it, teams should ask what worked well, what didn’t, and how things can be improved moving forward. It’s about striving for perfection through small, incremental changes, often referred to as kaizen, which help teams stay flexible and efficient.

Benefits of lean project management

Greater efficiency and less wastage are the primary goals of the lean methodology, but there are some additional benefits to also consider. Here are some of the top benefits of lean project management.

- Increased efficiency: By focusing on eliminating waste and streamlining processes, lean helps teams work more efficiently. Tasks are completed faster, bottlenecks are reduced, and unnecessary steps are cut, which leads to smoother project delivery.

- Cost reduction: Lean is designed to identify and eliminate wasteful activities, which directly reduces costs. Teams avoid overproduction, unnecessary resource use, and delays that can add financial strain to projects.

- Enhanced customer satisfaction: Since lean focuses on identifying and delivering what the customer truly values, the end result is a product or service that meets their exact needs. This leads to better customer satisfaction and can also foster stronger relationships with clients.

- Improved adaptability: Lean promotes continuous reflection and improvement, making it easier to adapt to new information, changes in scope, or unexpected challenges. The methodology encourages teams to remain flexible, adjusting plans and processes as needed.

- Faster delivery times: With lean’s focus on creating a smooth flow and eliminating delays, project timelines can be shortened without sacrificing quality. This is especially beneficial in industries where time-to-market is crucial.

Should your organization use lean project management?

If your company often faces resource constraints, tight deadlines, or fluctuating project demands, you should consider lean project management as a structured way to prioritize what matters most and eliminate what doesn’t.

Additionally, lean’s ability to quickly adapt to changes allows organizations to pivot efficiently without adding significant overhead or delays. By focusing on what adds value to the customer and constantly improving processes, businesses can stay agile and competitive in their markets.

As for companies in industries such as manufacturing, software development, healthcare, or construction, where waste and inefficiency have a huge impact on the bottom line, lean project management would be particularly useful.

Whether your goal is cost savings, faster delivery times, or simply a more engaged and efficient workforce, the lean methodology is a proven way to meet those objectives.

For a look at comprehensive project management tools that could enhance lean practices, check out this list of the top project management software of 2024.

Frequently asked questions (FAQs)

What is the difference between lean and agile?

Lean and agile project management share some commonalities, such as their emphasis on flexibility and continuous improvement, but they differ in focus and execution.

- Lean aims primarily at eliminating waste and optimizing processes for efficiency, while agile focuses on adaptability and delivering working increments of a project quickly.

- Agile is more iterative, with short cycles of development, review, and adaptation, whereas lean is about creating a value-driven, waste-free flow.

- Lean often influences agile practices, but agile tends to focus more on frequent delivery and feedback loops.

Is scrum lean or agile?

Scrum is primarily an agile methodology. It focuses on delivering work in short cycles or sprints, where teams regularly reassess and adapt based on feedback. However, some elements of scrum align with lean principles, such as minimizing waste and emphasizing continuous improvement. Still, scrum’s core framework is built around agile values and principles.

Is kanban agile or lean?

Kanban has roots in lean manufacturing but is widely used in agile environments today. Kanban is focused on optimizing workflow and reducing bottlenecks, which is a core lean concept. However, it’s now often used within agile teams to visualize work and manage flow, making it compatible with both methodologies. Therefore, while kanban comes from lean thinking, its flexibility makes it useful for agile practices.